Struggling to find a reliable cooling towel supplier? Poor quality and missed deadlines can ruin your launch. I’ll show you the key factors for a successful partnership.

To choose the best cooling towel manufacturer, you must vet their experience with performance fabrics, check for key certifications like OEKO-TEX, confirm low MOQs for market testing, and demand clear, all-in pricing. A good partner simplifies production, ensuring you get a quality product without hidden surprises.

Choosing the right manufacturer is one of the biggest decisions you’ll make. It directly impacts your product quality, your brand’s reputation, and your bottom line. I’ve spent years in the textile industry, so I know how overwhelming it can feel. But it doesn’t have to be. Let’s break down what really matters when you’re making this choice.

Who makes the best cooling towels?

Searching for the single "best" manufacturer can feel overwhelming. So many factories claim top quality, but I’ve seen firsthand how few actually deliver. The best partner is one who meets your specific needs consistently.

The best cooling towels come from manufacturers with deep expertise in performance microfiber and evaporative cooling technology. Look for suppliers like us at TowelTrend who offer full certifications, low MOQs, and proven quality control. "Best" means reliable, scalable, and a perfect fit for your brand.

I get asked this question a lot. The truth is, "best" depends entirely on your goals. For a promotional company, "best" might mean the lowest possible price for a one-time event. For a premium sports brand, it means the highest performance and durability. I’ve learned the "best" manufacturer is really the right manufacturer for you. You need to evaluate them on a few key points.

Technical Expertise

Does the manufacturer truly understand the science behind their product? They should be able to explain exactly how their towels achieve a cooling effect. Ask them about the specific microfiber blend, the yarn denier, and the knitting structure. If they can only talk about price, it’s a red flag. A knowledgeable partner will discuss how these technical details impact performance, feel, and durability.

Production Flexibility

Your business needs will evolve. You might launch with a small test order of 100 pieces but need to scale to 5,000 when a product goes viral. Can the manufacturer support that growth? Ask directly about their production capacity, their lead times for reorders, and if they charge penalties for small runs. At TowelTrend, we built our entire business model on this kind of flexibility, because we know how important it is for growing brands.

Partnership and Support

A great manufacturer is more than just a factory; they are a partner in your success. Do they offer design support or help with packaging? Can they handle complex shipping logistics, like sending inventory directly to Amazon FBA warehouses? The right partner removes friction and makes your job easier.

What fabric is used for cooling towels?

Are you confused by all the different fabric claims? Choosing the wrong material means your towel won’t cool effectively, leaving customers disappointed. The secret lies in a specific type of performance microfiber.

Cooling towels are almost always made from a specially engineered microfiber fabric. This material, typically a blend of polyester and polyamide, has a unique structure that rapidly absorbs water and promotes fast evaporation. This physical process is what creates the noticeable cooling effect against your skin.

The fabric is the absolute heart and soul of a cooling towel. It’s not the same as the microfiber cloth you use for cleaning. The performance comes from a very specific material composition and construction. After years of testing different textiles, I can tell you that two factors are critical.

The Microfiber Blend

Most cooling towels use a blend of polyester and polyamide, which you might also know as nylon. Polyester provides structure and makes the towel durable. Polyamide adds softness and dramatically increases absorbency. The ratio between these two fibers is very important. You’ll often see blends like 80/20 or 85/15 polyester-to-polyamide. This balance delivers both durability and a high-performance cooling effect.

The Weave and Structure

The way these tiny fibers are knitted together is just as important as the blend. The process creates a fabric with millions of tiny channels and an enormous surface area. This structure allows the towel to do two things perfectly: soak up a lot of water very quickly, and then release it efficiently through evaporation. When that water evaporates, it takes heat with it, which is what cools the fabric down. I always tell my clients to request a sample. You need to feel the unique, soft, and lightweight weave for yourself.

| Feature | Cooling Towel Microfiber | Standard Cotton Terry |

|---|---|---|

| Cooling Effect | High (Evaporative) | Low (Gets heavy and warm) |

| Absorbency | Excellent | Good |

| Drying Speed | Very Fast | Very Slow |

| Weight When Wet | Very Light | Heavy and Drippy |

What is a super cooling towel?

Have you heard the term "super cooling towel" and wondered if it was just marketing hype? It sounds like a gimmick. But it actually refers to a real enhancement in cooling technology.

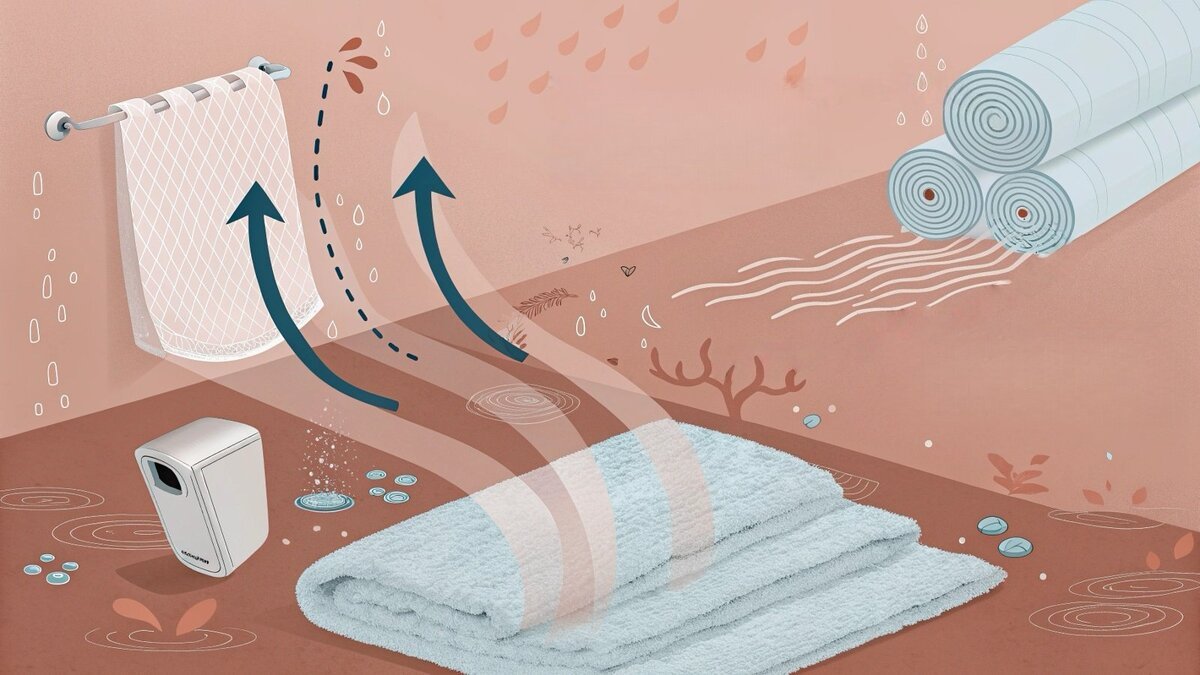

A super cooling towel is an advanced version that often uses a special mesh or multi-layered fabric. This enhanced construction holds more water and controls its evaporation rate more effectively. The result is a cooling sensation that feels more intense and lasts much longer—often for several hours.

In my experience, "super" isn’t just a marketing buzzword here. It signifies a genuine step up in performance and endurance. A standard cooling towel is fantastic for a quick cool-down at the gym. But a super cooling towel is engineered for more extreme conditions. Think of athletes on the field, construction workers in the summer sun, or anyone needing relief for extended periods. The difference comes down to a couple of key innovations.

Advanced Material Construction

These towels often feature a more complex design. Some use a patented mesh material that feels almost dry to the touch while staying cold. Others have a multi-layer construction. An outer layer might provide fast wicking, while a core layer acts as a reservoir, regulating the release of water to prolong the evaporative process. The goal is to prevent the towel from drying out too quickly, maximizing the cooling duration.

Extended Cooling Time

The main benefit here is time. A standard cooling towel is effective, but you might need to re-wet it every hour or so in high heat. A super cooling towel is designed to last for hours with a single activation. When we source these materials, we test them specifically for this. A simple "soak, wring, snap" process should provide consistent cooling for a much longer time. This extended performance is a powerful selling point for customers who rely on it.

What is the technology of cooling towels?

Do you wonder how a simple piece of fabric can feel so cold? It seems almost impossible without chemicals or some kind of refrigeration. The answer is based on a simple, powerful, natural process.

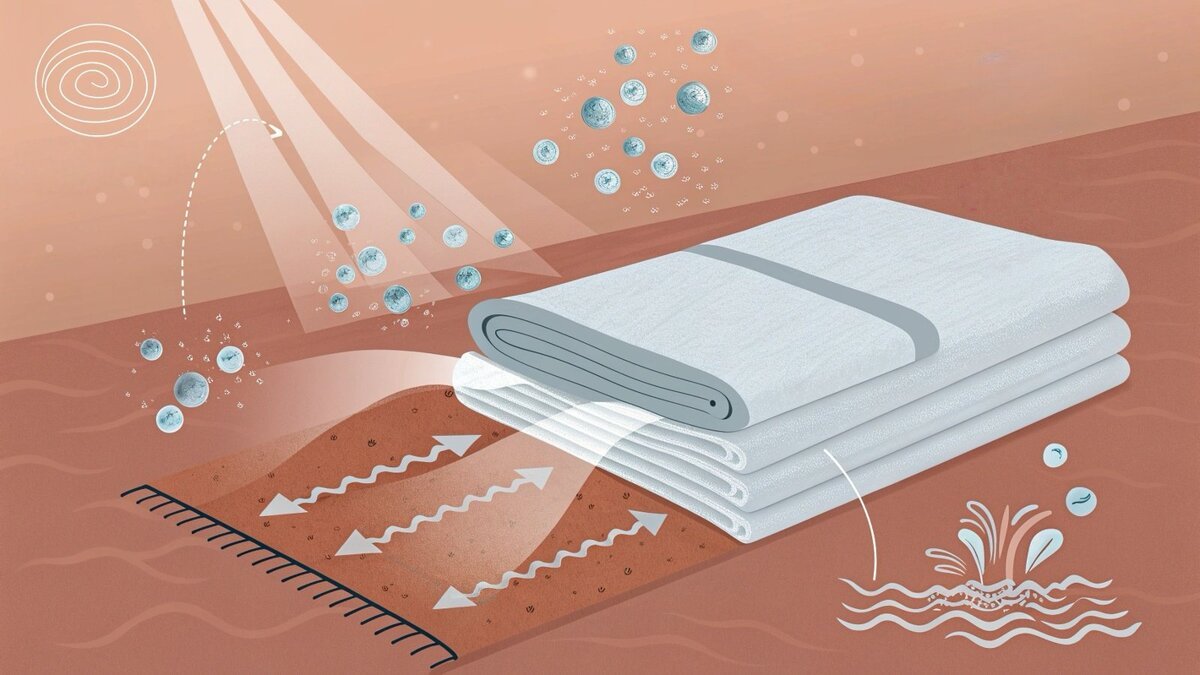

The technology behind cooling towels is evaporative cooling. The special microfiber fabric absorbs water, and when you snap it, air circulates through the material. This airflow accelerates evaporation, which pulls heat energy away from the fabric and your skin, creating a powerful cooling sensation.

This is my favorite part to explain because it’s pure, simple physics. There are no chemicals, no cooling gels, and no tricks. The towel is just designed to make a natural process happen very, very efficiently. As a manufacturer, we focus on perfecting the fabric to optimize this process. Let me break it down into the three simple steps.

Step 1: Absorption (The Soak)

First, you get the towel wet. The fabric is hydrophilic, which is a technical way of saying it loves water. The polyamide fibers in the blend and the capillary action of the weave structure pull water deep into the towel instantly. It can absorb many times its own weight in water without feeling bulky.

Step 2: Water Retention (The Wring)

Next, you wring out the excess water. The towel’s construction is designed to trap water molecules within its core structure. This is key. It holds onto just enough water to power the cooling effect but not so much that it drips all over you.

Step 3: Evaporation (The Snap)

This is where the magic happens. Snapping the towel forces air to circulate rapidly through the water-saturated fibers. This airflow dramatically speeds up the natural rate of evaporation. For water to turn from a liquid into a gas (evaporate), it needs energy. It pulls that energy in the form of heat directly from its surroundings—the towel and your skin. This transfer of heat is what makes the fabric feel so refreshingly cold.

Conclusion

Choosing the right manufacturer is key. Focus on their fabric technology, production flexibility, and certifications to find a true partner who delivers quality cooling towels and helps your brand grow.